Table of Contents

- Introduction

- Demystifying Stud Welding

- Unveiling the Basics: A Preview

- Understanding Stud Welding

- The Essence of Stud Welding

- Components and Mechanism

- Applications and Advantages

- Versatility in Applications

- Advantages that Elevate Projects

- Design Considerations

- Precision in Design for Stud Welding

- Selecting the Right Stud Type

- Installation Best Practices

- Ensuring Seamless Integration

- Safety Measures for Stud Welding

- FAQs about Stud Welding (Schema Format)

- Q1: What is the fundamental principle of stud welding?

- A1: Stud welding involves the fusion of a fastener (stud) to a base metal, creating a strong and permanent connection.

- Q2: What are the common applications of stud welding?

- A2: Stud welding is versatile, used in construction, fabrication, shipbuilding, and various industries for fastening components.

- Q3: How does stud welding contribute to project efficiency?

- A3: Stud welding enhances project efficiency by providing a quick and reliable method for creating strong connections.

- Q4: What safety measures should be followed during stud welding?

- A4: Safety measures include proper training, personal protective equipment (PPE), and adherence to industry standards.

- Q5: Can stud welding be used in different environments and conditions?

- A5: Yes, stud welding is adaptable to various environments, including challenging conditions such as high humidity or confined spaces.

- Stud Welding Services: Elevating Your Projects

- Subheading: Transformative Solutions

- Showcase of Expertise

- Advantages of Choosing Our Stud Welding Services

- Conclusion: Powering Projects with Stud Welding

Introduction

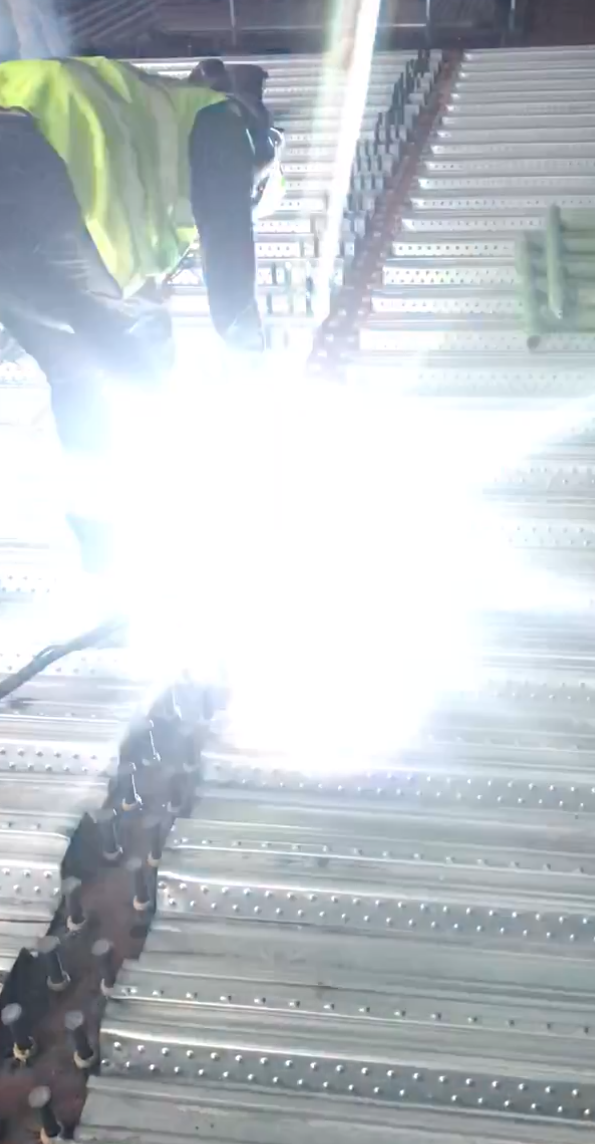

Demystifying Stud Welding

Stud welding, a fundamental process in construction and fabrication, involves the fusion of a fastener (stud) to a base metal, creating a strong and permanent connection. In this comprehensive guide, we demystify the intricacies of stud welding, providing a clear understanding of the process, its applications, and the advantages it brings to various industries.

Unveiling the Basics: A Preview

As we unravel the basics of stud welding, our aim is to equip professionals with the knowledge needed to leverage this transformative technique in their projects. From understanding the components and mechanism to exploring design considerations and installation best practices, this guide serves as a roadmap for those seeking to harness the power of stud welding.

Understanding Stud Welding

The Essence of Stud Welding

At the heart of stud welding lies the efficient and reliable process of creating strong connections. This section delves into the essence of stud welding, highlighting the key principles that make it a preferred method for fastening in construction, fabrication, shipbuilding, and various industrial applications.

Components and Mechanism

- Fastener (Stud): The fastener, or stud, is a crucial component fused to the base metal. Studs come in various types, each designed for specific applications.

- Base Metal: The base metal serves as the anchor for the stud. It can be made of materials such as steel, aluminum, or stainless steel.

Applications and Advantages

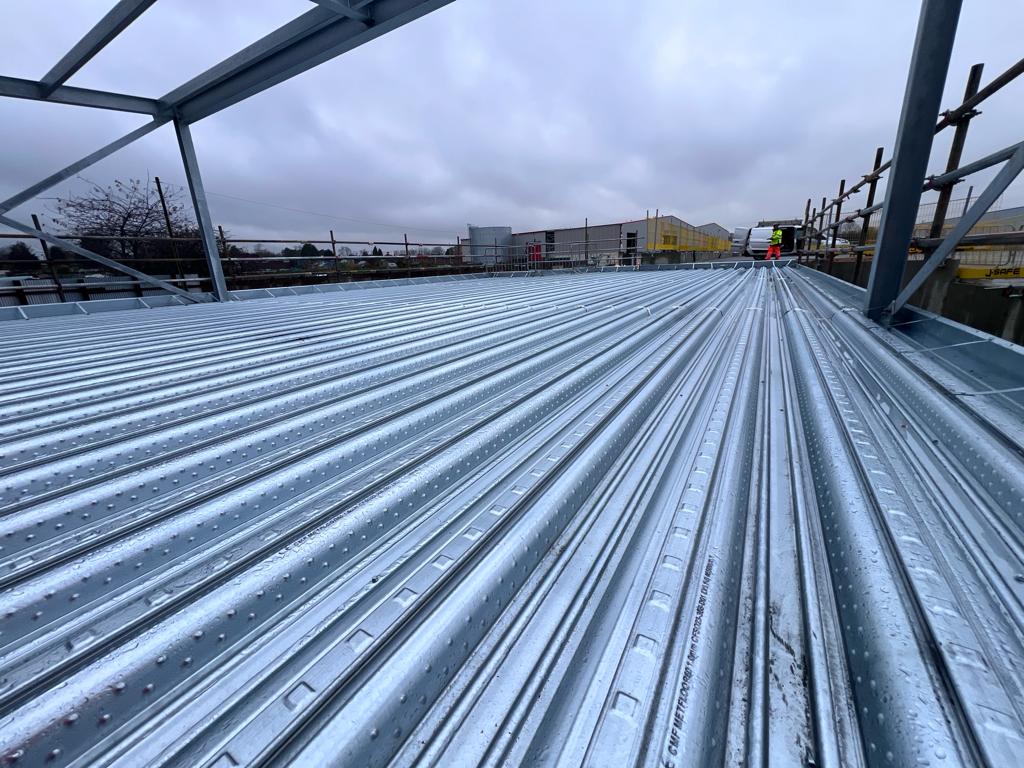

Versatility in Applications

Stud welding’s versatility extends across a wide range of applications, making it an invaluable technique in diverse industries. This section explores common applications, from attaching insulation to securing components in fabrication projects.

Advantages that Elevate Projects

- Speed and Efficiency: Stud welding provides a rapid and efficient method for creating strong connections, contributing to overall project timelines.

- Strength and Reliability: The fusion of the stud to the base metal creates a robust and reliable connection, ensuring the structural integrity of the project.

Design Considerations

Precision in Design for Stud Welding

Designing with stud welding in mind requires precision to ensure optimal results. This section guides professionals on selecting the right stud type and considering factors such as material compatibility and load-bearing requirements.

Selecting the Right Stud Type

- Threaded Studs: Suitable for applications requiring additional strength and the ability to fasten components securely.

- Flanged Studs: Ideal for projects where a larger surface area is needed for improved stability.

Installation Best Practices

Ensuring Seamless Integration

Proper installation is crucial for the success of stud welding projects. This section provides a guide to seamless integration, covering essential steps from preparation to layout and fastening.

Safety Measures for Stud Welding

- Training: Ensure that personnel involved in stud welding are properly trained in the use of equipment and safety procedures.

- Personal Protective Equipment (PPE): Mandate the use of PPE, including eye protection and welding gloves, to minimize the risk of injuries.

FAQs about Stud Welding

Q1: What is the fundamental principle of stud welding?

A1: Stud welding involves the fusion of a fastener (stud) to a base metal, creating a strong and permanent connection.

Q2: What are the common applications of stud welding?

A2: Stud welding is versatile, used in construction, fabrication, shipbuilding, and various industries for fastening components.

Q3: How does stud welding contribute to project efficiency?

A3: Stud welding enhances project efficiency by providing a quick and reliable method for creating strong connections.

Q4: What safety measures should be followed during stud welding?

A4: Safety measures include proper training, personal protective equipment (PPE), and adherence to industry standards.

Q5: Can stud welding be used in different environments and conditions?

A5: Yes, stud welding is adaptable to various environments, including challenging conditions such as high humidity or confined spaces.

Stud Welding Services: Elevating Your Projects

Transformative Solutions

Highlight the unique features and capabilities of your stud welding services. Showcase how your expertise and advanced techniques can provide transformative solutions for a wide range of projects.

Advantages of Choosing Our Stud Welding Services

- Expertise: Emphasize the experience and knowledge your team brings to the table in delivering stud welding services.

- Cutting-Edge Technology: Showcase any advanced stud welding technologies or techniques that set your services apart from the competition.

Conclusion: Powering Projects with Stud Welding

In conclusion, the basics of stud welding offer a powerful solution for professionals in construction and fabrication. By understanding the essence of stud welding, exploring its applications, and embracing design considerations and installation best practices, professionals can harness the full potential of this transformative technique.